The costs of safety: Millions of dollars in fines each year for companies and directors; over 256 convictions in Ontario

Only last week, Ontario secured two convictions involving worker safety: Rex Pak in Toronto for $60,000, and Monaghan Mushrooms Ltd, with a fine of $90,000. There are 256 convictions in Ontario carrying fines listed on the Ontario Government website.

These fines are fairly typical and do not include any personal lawsuits brought by victims and their survivors based on the convictions — which tend to be substantially more costly.

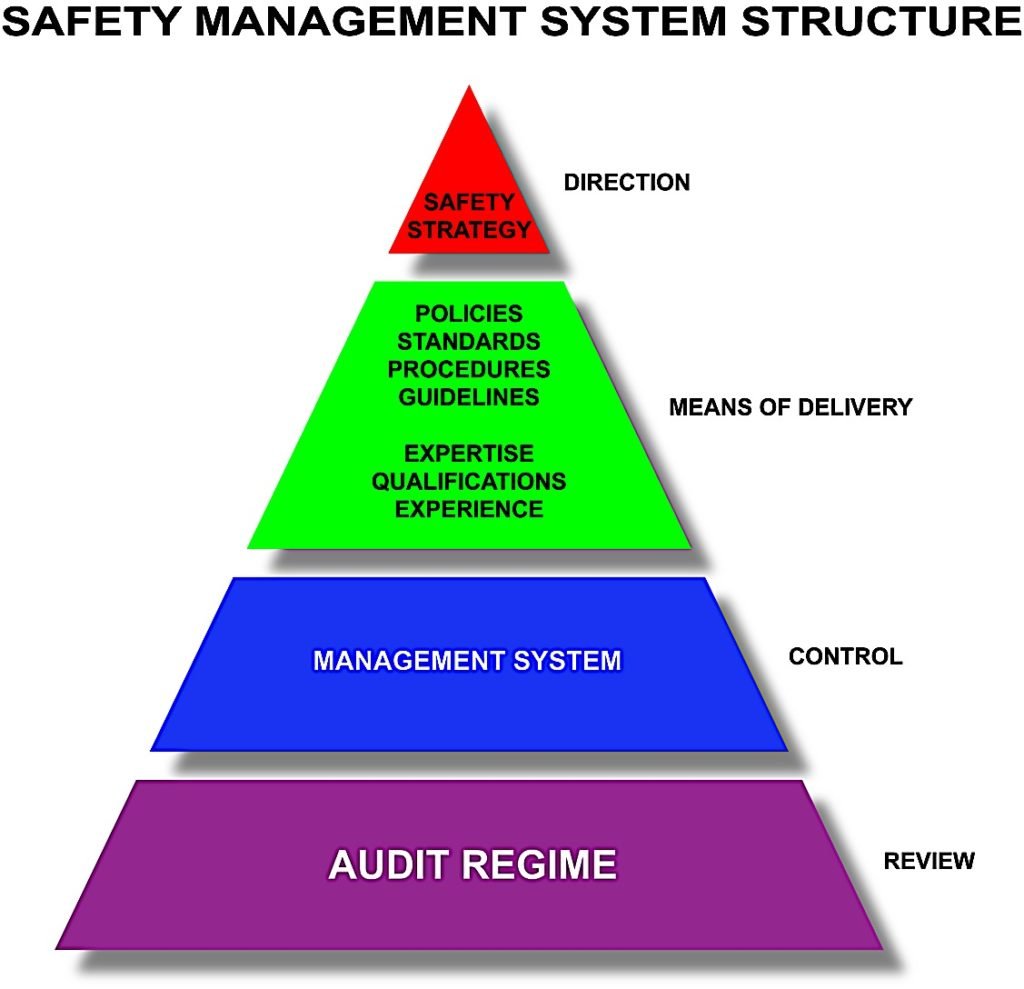

Often, a rigorous system of strategy and planning, policy and procedures, training and qualifying — especially qualifying your human resources — management systems day-to-day, and a safety audit regime will prevent these costly incidents. This is where an outsourced HR Management team can give you an extra layer of confidence in your policies and systems.

A quick review of occupational safety reveals a frightening scenario for managers and directors, with collectively millions in fines each year. The court bulletins on the Ontario government site list 256 convictions. Directors are especially vulnerable, as the conviction of Rex Pak’s director/officer demonstrates. Here are just some of the latest convictions:

- In January, Ottawa Permanent Roofing fined $80,000 for Occupational Health and Safety violations, after a fire broke out. [2]

- Canadian Natural Resources: $122,000 for H2S leak. [3]

- Dyno Nobel Canada fined $40,000 for a “fly rock.” [4]

- Prokleen Washing Services fined $105,000 in the asphyxiation death of a worker. [5]

- Just last week, a second conviction for Monaghan Mushrooms Ltd, after a collision between a pallet truck and forklift; fined

- $90,000 plus a victim surcharge. A previous conviction for fatality $140,000. [6]

- Ace Bakeries fined $55,000 after worker “suffered critical injuries” after a bread machine activated while a worker was performing routine maintenance. (Contravenes Section 76 of Ontario Regulation 851). [7]

- Steel tube injury Welded Tube of Canada Limited: $12,000 fine [8]

- $85,000 fine for 2132857 Ontario Ltd for a high-pressure water device fatality. At the time the company operated under a different name. [9]

- $75,000 fine for Arcelormittal after a worker is critically injured connecting coils to a hoist with a chain. [10]

These are just recent convictions (last two months). There are many charges still before the courts.

Strategy, planning, policy, proceedures, training, qualifying and safety audits all important

In the case of Rex Pak’s conviction, the “employer” — in this case, the director — was found not to have “ensured that safety measures and procedures were carried out.” This contravenes Section 25(1)(c) of the Occupational Health and Safety Act: “an employer shall ensure that measures and procedures prescribed are carried out in a workplace.” In this case, the worker did not turn off an agitator, attached to a hopper, and then placed a hand on a moving drive belt. This was likely preventable with the right set of guidelines, some planning and training for all employees, including managers/directors. In this case, the Ontario investigators reported: “One of the directors of Rex Pak, Denise Sabatini, was charged under section 32(a) of the act with failing as a director/officer of the company to take reasonable care between December 2016 and February 24, 2017, to ensure that Rex Pak complied with section 25 of the regulation.”

No written plans = strong liability

In the case of Ottawa Permanent Roofing, fined $80,000, they had not provided either written emergency procedures nor even a fire extinguisher on site. These types of oversights are not uncommon on work sites, especially mobile sites — where the locations change — but as the conviction shows, liability remains firmly with the employer.

[Does your company not have an up-to-date emergency procedure plan? The HR Management experts at Pivotal HR Solutions can consult with you on identifying, assessing, and monitoring safety in your workplace. For advice at 1-855-378-7987, or use the contact form below.]

Latest case: pallet truck vs forklift

In the case of Monaghan Mushrooms Ltd, the company was found guilty when “it was later found that Monaghan had not developed or implemented any policies, procedures or training about which vehicles had the right of way. The Ministry of Labour’s investigation found that the three workers had differing beliefs about which vehicle had right of way.”

Compounding the issue, “The company had a prior record in relation to a fatality at the workplace. On December 20, 2011, a worker employed by a subcontractor was struck and killed by a front-end loader operating in reverse. Monaghan pleaded guilty and was convicted on April 8, 2014, of failing to take every precaution reasonable in the circumstances for the protection of a worker, contrary to section 25(2)(h) of the Occupational Health and Safety Act; at that time the company was fined $140,000.”

Prevention is critical: no steps should be missed.

Management is only part of the equation. In the case of the asphyxiation death at Prokleen (above), the “Ontario Ministry of Labour’s investigation found the company’s written plan did not adequately identify certain workplace hazards. In particular, an access point of a customer’s container was not equipped with warning signs as to the oxygen-depleted atmosphere of the tank.”

In the case of Ace Bakeries, the conviction was based on “Section 76 of Ontario Regulation 851 – the Industrial Establishments Regulation – provides that if the starting of a machine “may endanger the safety of any worker, control switches or other control mechanisms shall be locked out, and other effective precautions necessary to prevent any starting shall be taken.” In this case, while “the worker and the senior director of product development were making the adjustments in the mechanical cabinet, the supervisor closed the interlocked safety gate. This caused the bread machine to activate and cycle.”

Preventable accidents

Management often relies on the defence that “it was an accident.” However, as the increasing rate of convictions — and guilty pleas — indicate, Ontario’s government isn’t receptive to this rationale, especially if a company has not made a sincere effort to ensure all safety contingencies are covered by corporate and worker guidelines, safety measures, safety checks, safety equipment and necessary training.

For instance, in the case of the high-pressure water fatality (above), even though the court found the company had mandated operator-controlled triggers, “there was no policy or instruction required workers to use the operator-controlled trigger attachment.” In other words, equipment was available, and training was apparently not. The court found: “Section 25(2)(h) of the Occupational Health and Safety Act (OHSA) states that an employer shall take every precaution reasonable in the circumstances for the protection of a worker. The company failed to take the reasonable precaution of ensuring that the high-pressure water jetting wand used by a worker to clean catch basins on August 26, 2017, was equipped with an operator-controlled trigger to control the flow of water, contrary to section 25(2)(h) of the OHSA. This is an offence pursuant to section 66(1) of the act.”

Do you need help auditing your workplace for mandated policies and plans? Ask the experts at Pivotal HR Solutions for a consultation>>

Contact Pivotal

NOTES

[1] “Injury to worker results in fines for manufacturer, Director” >>

[2] Ottawa Permanent Roofing fined $80,000>>

[3] Canadian Natural Resources fined $122,000 for H2S leak>>

[5] Worker’s death in tank container results in $105K fine; Nitrogen in tank asphyxiated the worker>>

[6] “Second conviction for mushroom farm’s failure to protect worker>>

[7] Ace Bakeries fined $55,000 after worker injured in Mississauga>>

[8] Steel tube injury results in $12,000 for Welded Tube of Canada Limited>>

[9] High-pressure water device kills worker $85,000 fine for Mississauga company>>

[10] Workers injury results in $75,000 fine for Arcelormittal in Hamilton >>

Our HR solutions experts can recommend the right mix of HR outsourced services to make your entry into Canada easier.

Our HR solutions experts can recommend the right mix of HR outsourced services to make your entry into Canada easier.  Pivotal Employment Management Services co-hires your workforce, simplifying entry of your business in Canada.

Pivotal Employment Management Services co-hires your workforce, simplifying entry of your business in Canada.